A-Grade (High) Fire-Resistant Metal Wall Sandwich Panels

Full rock wool metal wall sandwich panel, use Baosteel aluminized zinc-coated steel coil, ROCKWOOL or Owens core material, etc. Products are fire-resistant, thermal insulated, waterproof, decorative, suitable for high-end industrial buildings with strict requirements on fifire-resistance.

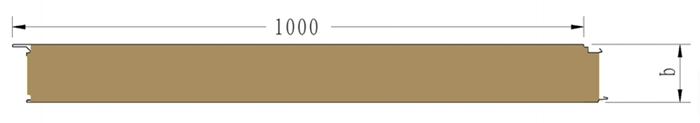

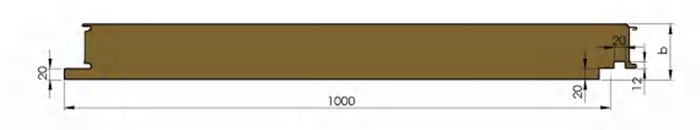

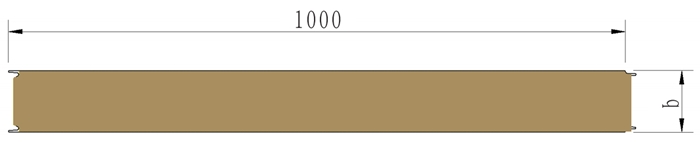

Hidden Screw Type Metal Wall Sandwich Panels

Plug-In Type Metal Wall Sandwich Panels (Obvious screw type)

![1625712139154266.jpg LVT[4YHFNN1O){(2MB_PD]A_副本.jpg](/Uploads/image/20210708/1625712139154266.jpg)

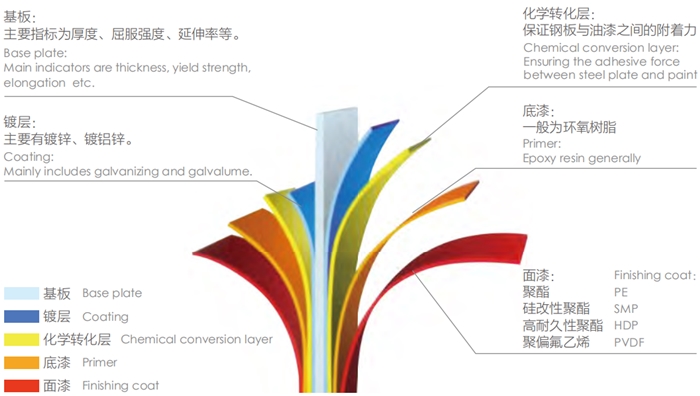

High-quality prepainted steel sheets

● Usually we would recommend our customers the coating, zinc content, and base plate which match with the usage and service life of buildings.

● Color-coated steel sheet are products that using hot dipped galvanizing or galvalume steel plate as substrate after surface degreasing, parkerizing and chromating, baked with organic coatings.

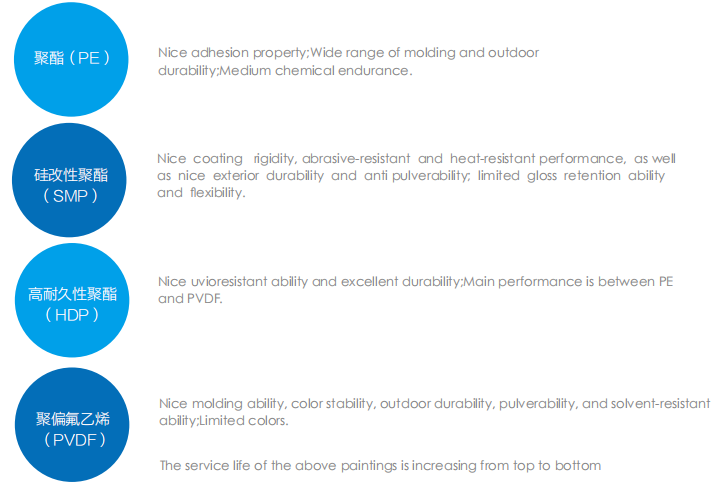

● The commonly used coating materials for color-coated steel sheets are PE, SMP, HDP, PVDF etc.

● Color-coated steel sheet can be classified as general usage and structural usage steels. The specific grades are TDC51D, TDC52D, TS280GD, TS330GD, TS350GD, TS550GD.

● The coating structures usually is twice-baking-after twice-painting coat, with the coating thickness of over 20μm for the outside sheet, and 5-12μm at the back side. The current operative standards of the color-coated steel sheet include: Chinese GB/T 12754-2006, America ASTM A755 (galvanized), ASTM A792 (galvalume), Japan JIS G3322, Europe EN/10169, and South Korea KS D3506.

We will pay special attention to the following performance of prepainted steel sheets

● The type and the thickness of coating

● The hardness and glossiness of pencil

● T-bending test and impact test

● Mechanical property(yield stength,tensile strength,elongation)

● Anti-corrosion(salt fog)property

● Anti-fading and anti-pulverability property

● Anti-dust property

Classification of top coat of color-coated steel sheet

Ral color

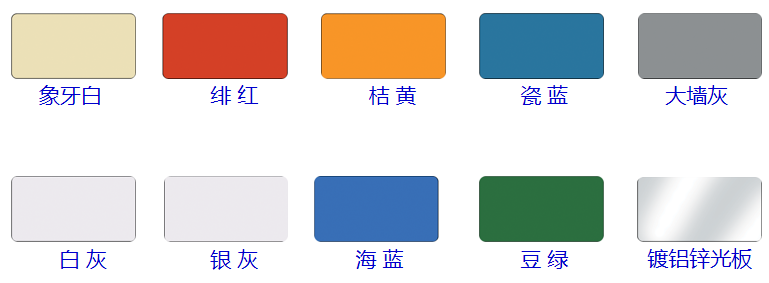

What's the features of our new model fireproof rock wool sandwich panel ?

Taking high-quality natural rocks such as basalt, gabbro and others as main materials, the core material of our new type fireproof rock wool sandwich panel is a kind of artificial inorganic fiber after the process of high temperature melting and fiberization with the characteristics of very low slag and dust content and non-absorbent. It is "real rockwool"!

Comparison picture of hydrophobicity test

The test shows that our new type rockwool sandwich panel possesses higher hydrophobicity comparing with conventional rock wool sandwich panel.

Advantages of the new type rock wool

● The type and the thickness of coating

● The hardness and glossiness of pencil

● T-bending test and impact test

● Mechanical property(yield stength,tensile strength,elongation)

● Anti-corrosion(salt fog)property

● Anti-fading and anti-pulverability property

● Anti-dust property

Disadvantages of conventional mineral wool/slag wool:

Due to its high dust content and low acidity coefficient,it has a strong corrosive effect on metals.

Its high hygroscopicity can lead to a sharp decline in thermal insulation performance, thus cold bridge phenomenon is easy to happen.

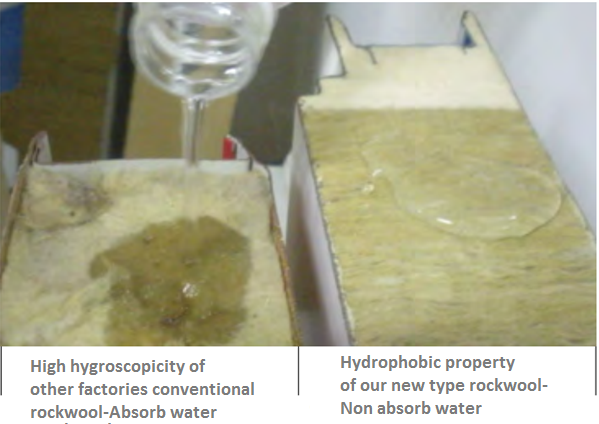

Core material index of new model fireproof rock wool sandwich panel

![1624546777735456.png VKGYKTRON7CW(031)$MU]AF_副本.png](/Uploads/image/20210624/1624546777735456.png)

High fifireproof Metal Wall Sandwich Panel Specifification & Permissible Load Sheet (Allowed Deformed f≤1/200)

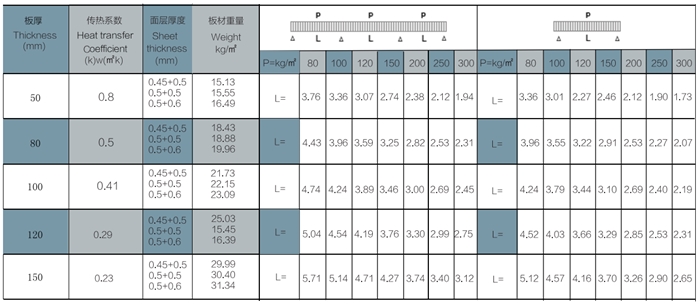

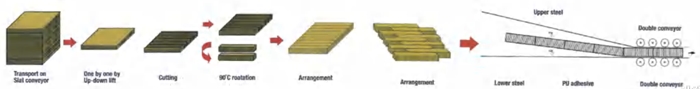

Production procedure

![1625712772127186.jpg O(QBA%AO[U[6H]E%093$C4L_副本.jpg](/Uploads/image/20210708/1625712772127186.jpg)

A. Decoil Machine

B. Molding Press Machine

C. Preheating Room

D. Spread Sealant Device

E. Double-Crawler Machine

F. Cutting Machine

G. Stow System

H. Packing System

I. Rock Wool Strip Cut,Transport System

J.Rock Wool Trapezoid Strip Cut,Transport System

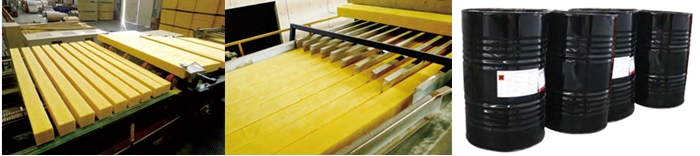

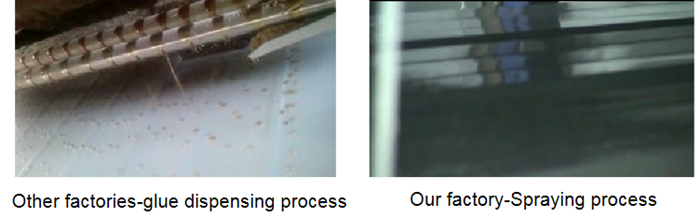

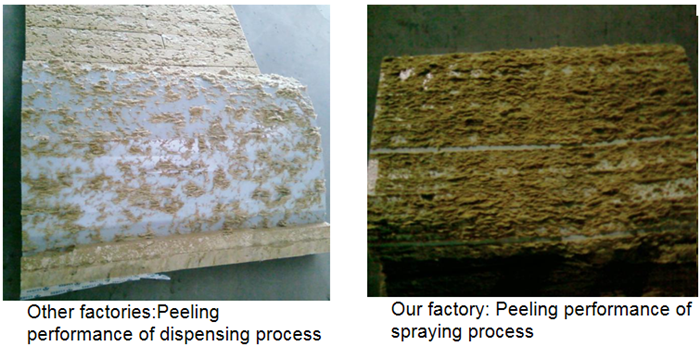

Advantages of the new type fireproof rockwool sandwich panel

● After a 90°rotation, the core material is vertical to the steel sheet, thus the panel's compressive strength increased by 100%.

● The vertical distribution and cross butting of core materials prevent the butting gap among core materials from existing, improve the strength while ensuring the flatness of the board surface.

● The imported high-efficiency binder with excellent fireproof performance is used on new products, and the new product binder is coated onto the steel sheet through the spraying way with a dosage up to 600g/m2 . The even and reliable bond makes the bonding rate nearly reach 100%.

Installation effect

Contact: International Department

Phone: +86-24-62293521

Tel: +86-24-62293521

Email: info@dwsteelbuilding.cn

Add: No.8, Shenyang, China