Product advantages

The tongue and groove joint structure improves the insulation and air tightness of the panels and is specially designed for cold storages.

The panels are uniform and stable and extremely excellent in both heat insulation and waterproofing.

The panels have light weights and beautiful appearances, solving the temperature difference problem of the cold storage industry effectively.

Within certain modulus, the cold storages may change freely in length, width and height directions to get bigger or smaller according to actual needs. The knockdown boards may be remounted at another place conveniently and quickly.

PIR Products

Polyisocyanurate is called PIR for short. For the composite boards developed by us, excessive isocyanurate is added and ring structure and higher isocyanurate index are employed in the compounds to form compact PIR products, thus ensuring greater stability and excellent heat and fire resistance for the internal rigid foams. Experiments show that the products can endure a temperature up to 200℃ in short time period or to 160℃ for long time.

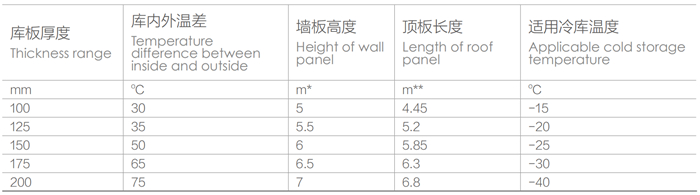

The technical specifications of cold storage sandwich panel

The data shown in the left table are only available for the panel which subject to the internal-external pressure difference and contraction pressure, without wind load. If the specified length/height is exceeded or wind load occurs, panel supporters are required.

The above data are calculated according to the heat flow of 8~10W/m2.

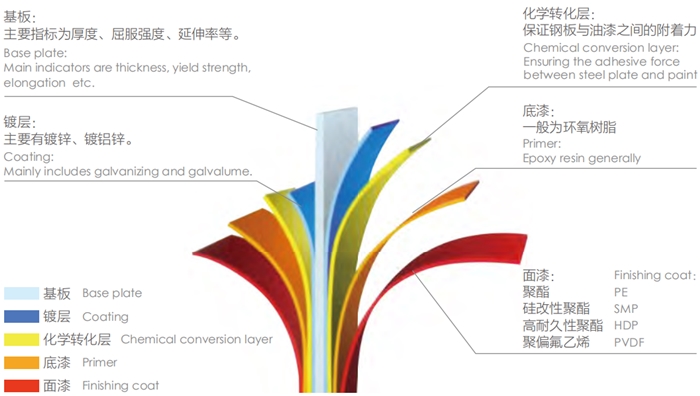

High-quality prepainted steel sheets

● Usually we would recommend our customers the coating, zinc content, and base plate which match with the usage and service life of buildings.

● Color-coated steel sheet are products that using hot dipped galvanizing or galvalume steel plate as substrate after surface degreasing, parkerizing and chromating, baked with organic coatings.

● The commonly used coating materials for color-coated steel sheets are PE, SMP, HDP, PVDF etc.

● Color-coated steel sheet can be classified as general usage and structural usage steels. The specific grades are TDC51D, TDC52D, TS280GD, TS330GD, TS350GD, TS550GD.

● The coating structures usually is twice-baking-after twice-painting coat, with the coating thickness of over 20μm for the outside sheet, and 5-12μm at the back side. The current operative standards of the color-coated steel sheet include: Chinese GB/T 12754-2006, America ASTM A755 (galvanized), ASTM A792 (galvalume), Japan JIS G3322, Europe EN/10169, and South Korea KS D3506.

We will pay special attention to the following performance of prepainted steel sheets

● The type and the thickness of coating

● The hardness and glossiness of pencil

● T-bending test and impact test

● Mechanical property(yield stength,tensile strength,elongation)

● Anti-corrosion(salt fog)property

● Anti-fading and anti-pulverability property

● Anti-dust property

Classification of top coat of color-coated steel sheet

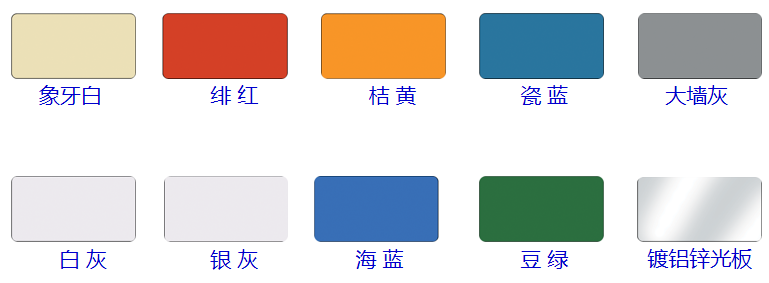

Ral color

Process flow

Industrial breakthroughs

The domestic first full automatic integrated production technology for soft and rigid surface composite boards. The production lines can continuously produce soft and rigid surface courses and energy-saving boards taking PUR, PIR, rockwool and glasswool as core materials, promising domestic foremost product updating and expanding technologies in the composite board production industry. It has broken through the idea that the production lines of metal-skinned sandwich panels are separated from that of the sandwich panels made of multiple kinds of flame retardant materials and heat insulating materials.

The equipment which produce PIR sandwich panel is a fully automated production line of the world's advanced Italian machinery manufacturer PUMA and German Krauss Maffei, with a total length of nearly 200 meters.

The domestic first six-component high-pressure continuous foaming and online batching and mixing production system

Application fields:

Fast frozen processing and refrigeration of food

Food processing plant

Storage of dairy products

Biological products and medicines

Indoor cold storge

Cold storages for cold-chain transportation vehicle

Installation effect

Contact: International Department

Phone: +86-24-62293521

Tel: +86-24-62293521

Email: info@dwsteelbuilding.cn

Add: No.8, Shenyang, China