It is a new type fire proof glass wool panel.

Glass wool core PIR rail wall panel is a new type fireproof glass wool sandwich panel, which is recombined into a beautiful, flat, and tough building panel by choosing two layers of high-quality color coated steel sheets or other precisely profiled metal sheets as its face steel sheet, rotating the stripped glass wool 90 degrees after roll forming (make the fibers vertical to the upper and lower steel sheets) and strongly binding high-quality glass wool with the metal face steel sheet using high-strength, high-adhesion, high-fire-prevention binder. Excellent fire-prevention, thermal insulation, environment protection and other characteristics of the formed boards provide a best choice for industrial building envelope system

High-quality prepainted steel sheets

● Usually we would recommend our customers the coating, zinc content, and base plate which match with the usage and service life of buildings.

● Color-coated steel sheet are products that using hot dipped galvanizing or galvalume steel plate as substrate after surface degreasing, parkerizing and chromating, baked with organic coatings.

● The commonly used coating materials for color-coated steel sheets are PE, SMP, HDP, PVDF etc.

● Color-coated steel sheet can be classified as general usage and structural usage steels. The specific grades are TDC51D, TDC52D, TS280GD, TS330GD, TS350GD, TS550GD.

● The coating structures usually is twice-baking-after twice-painting coat, with the coating thickness of over 20μm for the outside sheet, and 5-12μm at the back side. The current operative standards of the color-coated steel sheet include: Chinese GB/T 12754-2006, America ASTM A755 (galvanized), ASTM A792 (galvalume), Japan JIS G3322, Europe EN/10169, and South Korea KS D3506.

We will pay special attention to the following performance of prepainted steel sheets

● The type and the thickness of coating

● The hardness and glossiness of pencil

● T-bending test and impact test

● Mechanical property(yield stength,tensile strength,elongation)

● Anti-corrosion(salt fog)property

● Anti-fading and anti-pulverability property

● Anti-dust property

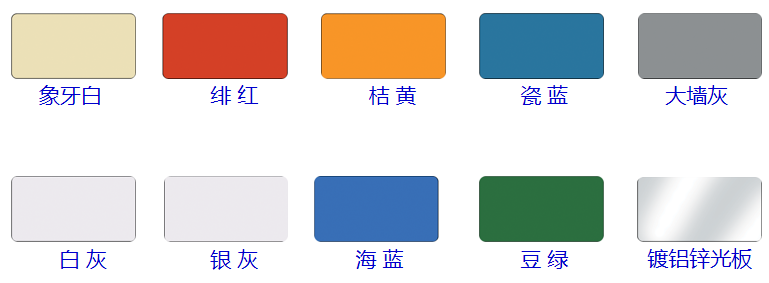

Ral color

What's the features of the new type fireproof glass wool sandwich panel ?

The core material of the new model fireproof glasswool sandwich panel composes of 5-8um-diameter thin and uniform glasswool fibers produced by applying high speed centripetal seperation process to original glass stone, and its interior is pure inorganic substance. The thermal insulation effect cannot abate as time goes by due to its compact and uniform overall structure.

Advantages of the new type glass wool

Non inflammabiliy and Level A fireproof performance

Hydrophobic property and high ageing resistance

Excellent performance in thermal insulation

Sound absorption and noise reduction

Biodegradable and environment-friendly

High acidity coefficient can greatly reduce the corrosive action on metals

Technical specification of new type fireproof glass wool sandwich panel

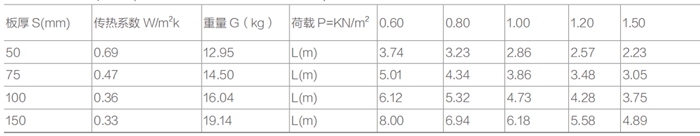

Allowable vertical load and thermal conductivity of the new type fireproof glass wool sandwich wall panel(allowable deflection f ≤ L/200)

Note: the values in the above table calculated on the basis of glasswool density of 64kg/m3 , 0.6mm outer steel sheet and 0.5mm inner steel

New model fireproof glass wool panel production line

● The equipment which produce glass wool sandwich panel is a fully automated production line of the world's advanced Italian machinery manufacturer PUMA and German Krauss Maffei, with a total length of nearly 200 meters.

● To further improve the panel's performance, such as metal skins' peel strength, no cold bridge and no dewing, 50mm PU/PIR edge sealing is added to both sides in the production process.

● The application of double crawler machine changes the traditional production process in which rolls keep a linear contact with steel sheets. By this way, rolls keep a plane contact with steel sheets, run synchronously with sandwich panels and solidify completely in double crawlers, thus the flatness of sandwich panels and the bonding stability between core materials and steel sheets are ensured.

Advantages of the new type fireproof glass wool sandwich panel

● After a 90°rotation, the core material is vertical to the steel sheet, thus the panel's compressive strength increased by 100%.

● The vertical distribution and cross butting of core materials prevent the butting gap among core materials from existing, improve the strength while ensuring the flatness of the board surface.

● The imported high-efficiency binder with excellent fireproof performance is used on new products, and the new product binder is coated onto the steel sheet through the spraying way with a dosage up to 600g/m2. The even and reliable bond makes the bonding rate nearly reach 100%.

Contact: International Department

Phone: +86-24-62293521

Tel: +86-24-62293521

Email: info@dwsteelbuilding.cn

Add: No.8, Shenyang, China